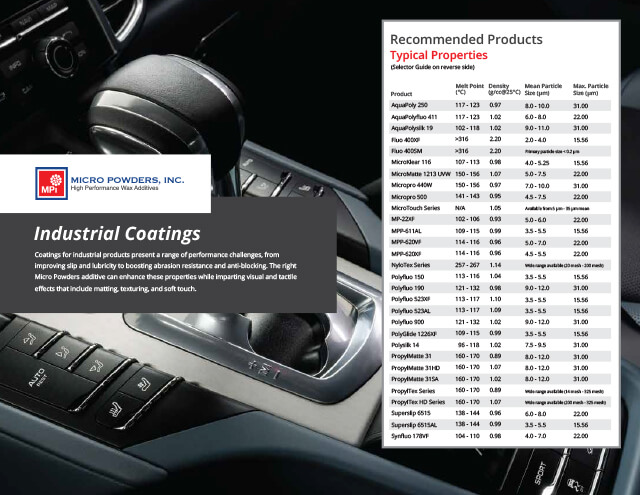

Industrial Coatings

Coatings for industrial products present a range of performance challenges, from improving slip and lubricity to boost abrasion resistance and anti-blocking. The right micronized wax additive can enhance these properties while imparting visual and tactile effects that include matting, texturing, and haptics.

PRODUCT(S) FOUND

AquaPoly 250

Request SampleA unique micronized polyethylene wax blend for maximum rub and scratch resistance with improved slip in aqueous systems

- A hard, high density modified polyethylene blend

- Provides outstanding rub, mar and scratch resistance

- Adds slip properties

- Imparts antiblocking

MicroKlear 116

Request SampleA micronized composite of polyethylene and carnauba wax for surface slip and scratch resistance with excellent clarity and gloss retention. Also useful in seed coatings.

- Provides an excellent combination of slip, abrasion resistance, and scratch resistance

- Ideal for applications where excellent gloss and clarity are required

- In coil coatings, provides maximum slip for forming and fabrication of finished coil

- Reduces coil coating surface haze post-bake and water quench

- Provides excellent slip, scratch resistance and food release properties in metal packaging coatings

MicroMatte® 1213 UVW

Request SampleA modified polypropylene wax densified with silica for consistent gloss control with clarity and stability in water based and UV/EB coatings

- Effective gloss control with good in-can stability

- Adds slip with scratch and mar resistance

- Nonabrasive wax technology imparts a smoother surface feel vs. silica-based additives

- Provides burnish and blocking resistance

- Improved film clarity vs. MicroMatte 1011 UVW

Micropro 440W

Request SampleModified polypropylene wax for consistent gloss control with mar and abrasion resistance, specifically formulated for stability in water based paints and coatings

- Improves mar, scratch and metal marking resistance

- Uniform gloss reduction with good burnish resistance in low or medium gloss finishes

- Imparts a smooth surface "feel"

- Will not powder or chalk in exterior applications

- Low density will keep silica matting additives in suspension

Micropro 500

Request SampleA higher molecular weight modified hybrid polypropylene wax for consistent gloss control with mar and abrasion resistance

- Improves mar, scratch and metal marking resistance

- Effective gloss control agent with good burnish resistance in low or medium gloss finishes

- Improved solvent resistance vs. Micropro 400

- Imparts antiblocking

- Low density will keep silica matting additives in suspension

Microspersion® 1226XF-50

Request SampleA water based dispersion of a highly engineered HDPE/ceramic/nanoceramic composite for abrasion resistance and lubricity.

- Convenient, ready-to-use, pourable water based wax dispersion

- HDPE composite reinforced with hard, inert ceramic microspheres and nanoceramic platelets

- Improved Taber abrasion resistance when compared to PE/PTFE additives

- Provides slip and lubricity

- Ideal for can and container coatings; 21CFR 175.300 approved

- Effective replacement for PTFE additives

Microspersion® 1213 UVW

Request SampleA water based anionic dispersion of modified polypropylene wax, densified with silica for consistent gloss control with clarity and stability in water based and UV/EB coatings

- Convenient, ready-to-use, pourable anionic acrylic-stabilized wax dispersion

- Effective gloss control with good in-can stability

- Adds slip with scratch and mar resistance

- Nonabrasive wax technology imparts a smoother surface feel vs. silica-based additives

- Provides burnish and blocking resistance

Microspersion® 250-50

Request SampleA water based dispersion of micronized oxidized polyethylene wax for maximum rub and scratch resistance with improved slip in aqueous systems

- Convenient, ready-to-use, pourable water based wax dispersion

- A hard, high density modified polyethylene blend

- Provides outstanding rub, mar and scratch resistance

- Adds slip properties

- Imparts antiblocking

Microspersion® 31HD-40

Request SampleA water based dispersion of finely micronized densified polypropylene for consistent matting and gloss control with superior in-can stability in water based paints, coatings and inks

- Convenient, ready-to-use, pourable water based wax dispersion

- Efficient gloss reduction from satin to matte finish

- Improves burnish resistance vs. silica mattifiers

- Particle density optimized to essentially eliminate flotation or settling in most water based systems

- Imparts anti-slip properties

Microspersion® 440W

Request SampleAn anionic water based dispersion of modified polypropylene wax for consistent gloss control with mar and abrasion resistance, specifically formulated for stability in water based paints and coatings

- Convenient, ready-to-use, pourable anionic acrylic-stabilized wax dispersion

- Improves mar, scratch and metal marking resistance

- Uniform gloss reduction with good burnish resistance in low or medium gloss finishes

- Imparts a smooth surface "feel"

- Will not powder or chalk in exterior applications

Microspersion® 611AL-50

Request SampleA water based dispersion of a highly engineered HDPE/aluminum oxide nanocomposite for unsurpassed scratch and scuff resistance

- Convenient, ready-to-use, pourable water based wax dispersion

- Maximum scratch and abrasion resistance with slip and lubricity

- HDPE composite reinforced with 300 nm aluminum oxide nanoparticles (Mohs Hardness 9)

- Composite particle density maximizes efficiency and minimizes settling

- Extra fine particle size provides excellent gloss retention and film clarity

Microspersion® 620VF-50

Request SampleA water based dispersion of high performance micronized polyethylene wax which provides a unique combination of surface slip, abrasion/rub resistance, and antiblocking in a wide variety of coatings and inks

- Convenient, ready-to-use, pourable water based wax dispersion

- Imparts excellent abrasion, rub and mar resistance with good surface slip

- Provides excellent antiblocking properties

- Adds heat resistance

- Better resistance to solvent absorption and swelling when compared to synthetic waxes

Microspersion® R331-50

Request Sample

A anionic water based dispersion of finely micronized rice bran wax for use in industrial coatings and agrochemical products

- Convenient, ready-to-use, pourable anionic wax dispersion

- Natural wax

- Excellent burnish and abrasion resistance compared to synthetic wax additives

- Biodegradable to OECD 302C test standard

- Improves lubricity, dust-off, and block resistance in seed coatings

- Effective dry powder binding agent

MicroTouch 800F

Request SampleHighly resilient spherical polyurethane beads that can modify the tactile properties of formulated coatings and inks while improving burnish, scratch and mar resistance

- Virtually indestructible elastic particles that distort when disturbed by a physical force and then return to their original spherical shape when the force is removed

- Provide different tactile effects ranging from satiny smooth to rubbery to leathery in properly formulated coatings

- Different particle sizes available to create a unique surface "touch"

- Improves burnish and abrasion resistance

- Effective gloss reduction

MicroTouch 800VF

Request SampleHighly resilient spherical polyurethane beads that can modify the tactile properties of formulated coatings and inks while improving burnish, scratch and mar resistance

- Virtually indestructible elastic particles that distort when disturbed by a physical force and then return to their original spherical shape when the force is removed

- Provide different tactile effects ranging from satiny smooth to rubbery to leathery in properly formulated coatings

- Different particle sizes available to create a unique surface "touch"

- Improves burnish and abrasion resistance

- Effective gloss reduction

MicroTouch 800XF

Request SampleHighly resilient spherical polyurethane beads that can modify the tactile properties of formulated coatings and inks while improving burnish, scratch and mar resistance

- Virtually indestructible elastic particles that distort when disturbed by a physical force and then return to their original spherical shape when the force is removed

- Provide different tactile effects ranging from satiny smooth to rubbery to leathery in properly formulated coatings

- Different particle sizes available to create a unique surface "touch"

- Improves burnish and abrasion resistance

- Effective gloss reduction

MicroTouch 800XXF

Request SampleHighly resilient spherical polyurethane beads that can modify the tactile properties of formulated coatings and inks while improving burnish, scratch and mar resistance

- Virtually indestructible elastic particles that distort when disturbed by a physical force and then return to their original spherical shape when the force is removed

- Provide different tactile effects ranging from satiny smooth to rubbery to leathery in properly formulated coatings

- Different particle sizes available to create a unique surface "touch"

- Improves burnish and abrasion resistance

- Effective gloss reduction

MicroTouch 850XF

Request SampleHighly resilient modified spherical polyurethane beads that can modify the tactile properties of formulated coatings and inks while improving burnish, scratch and mar resistance

- Virtually indestructible elastic particles that distort when disturbed by a physical force and then return to their original spherical shape when the force is removed

- Provide different tactile effects ranging from satiny smooth to rubbery to leathery in properly formulated coatings

- Modified to enhance surface slip and lubricity

- Improves burnish and abrasion resistance

- Effective gloss reduction

MP-22XF

Request SampleHigh performance, versatile grade of micronized synthetic wax for improved slip, scratch and rub resistance in a wide variety and paints, coatings and inks

- Imparts a high degree of lubricity and slip with rub and mar resistance

- Provides antiblocking properties

- Gives long-lasting water beading and weather resistance to exterior alkyd-based stains

- Consider MP-22C & MP-28C (spherical) for improved surface slip

- Biodegradable to OECD 302C test standard

- Not a microplastic per ECHA definitions

MPP-611AL

Request SampleA highly engineered HDPE/aluminum oxide nanocomposite for unsurpassed scratch and scuff resistance

- Maximum scratch and scuff resistance with slip and lubricity

- HDPE composite reinforced with 300 nm aluminum oxide nanoparticles (Mohs Hardness 9)

- Easier-to-disperse nanotechnology in a safe, non-nano powder

- Composite particle density maximizes efficiency and minimizes settling

- Effective replacement for PTFE additives

MPP-620VF

Request SampleHigh performance micronized polyethylene wax which provides a unique combination of surface slip, abrasion/rub resistance, and antiblocking in a wide variety of coatings and inks

- Imparts excellent abrasion, rub and mar resistance with good surface slip

- Provides excellent antiblocking properties

- Adds heat resistance

- Better resistance to solvent absorption and swelling when compared to Fischer-Tropsch (synthetic) waxes

MPP-620XF

Request SampleHigh performance micronized polyethylene wax which provides a unique combination of surface slip, abrasion/rub resistance, and antiblocking in a wide variety of coatings and inks

- Imparts excellent abrasion, rub and mar resistance with good surface slip

- Provides excellent antiblocking properties

- Adds heat resistance

- Better resistance to solvent absorption and swelling when compared to Fischer-Tropsch (synthetic) waxes

NatureFine R331

Request Sample

Finely micronized rice bran wax for use in industrial coatings and agrochemical products

- Natural food grade wax conforming to 21CFR 172.890

- Excellent burnish and abrasion resistance compared to synthetic wax additives

- Biodegradable to OECD 302C test standard

- Improves lubricity, dust-off, and block resistance in seed coatings

- Effective dry powder binding agent

- Microplastic alternative

NyloTex 140

Request SampleMicronized Nylon 66 for adding texture and surface durability to high temperature coatings

- Provides a uniform and controlled surface texture

- Imparts surface toughness and durability

- High melting point polymer is ideal for use in baking or high temperature curing systems

- Easy to disperse fine powder that can be incorporated with high speed mixing

- Adds texture in powder coatings

NyloTex 200

Request SampleMicronized Nylon 66 for adding texture and surface durability to high temperature coatings

- Provides a uniform and controlled surface texture

- Imparts surface toughness and durability

- High melting point polymer is ideal for use in baking or high temperature curing systems

- Easy to disperse fine powder that can be incorporated with high speed mixing

- Adds texture in powder coatings

NyloTex 50

Request SampleMicronized Nylon 66 for adding texture and surface durability to high temperature coatings

- Provides a uniform and controlled surface texture

- Imparts surface toughness and durability

- High melting point polymer is ideal for use in baking or high temperature curing systems

- Easy to disperse fine powder that can be incorporated with high speed mixing

- Adds texture in powder coatings

PolyGlide 1226XF

Request SampleA highly engineered HDPE/ceramic/nanoceramic composite for abrasion resistance and lubricity

- HDPE composite reinforced with hard, inert ceramic microspheres and nanoceramic platelets

- Improved Taber abrasion resistance when compared to PE/PTFE additives

- Provides slip and lubricity

- Ideal for can and container coatings; 21CFR 175.300 approved

- Effective replacement for PTFE additives

- Compare to (coarser) Polyfluo 900

PropylMatte 31

Request SampleFinely micronized polypropylene for efficient matting and gloss control in paints, coatings and inks

- Provides consistent gloss reduction with no effect on coating viscosity

- Tough, high molecular weight polymer imparts burnish and abrasion resistance

- Imparts anti-slip properties

- Density (0.89) ideal for solvent based systems

- For more efficient matting with a fine microtexture, try PropylTex 325S/270S

- Adds texture in low bake (Low E) powder coatings

PropylMatte 31HD

Request SampleFinely micronized densified polypropylene for consistent matting and gloss control with superior in-can stability in water based paints, coatings and inks

- Efficient gloss reduction from satin to matte finish

- Improves burnish resistance vs. silica mattifiers

- Particle density optimized to essentially eliminate flotation or settling in most water based systems

- Imparts anti-slip properties

- For more efficient matting with a fine microtexture, try PropylTex 325HD/270HD

PropylTex® 100S

Request SampleCoarse particle size grades of micronized polypropylene for adding texture, structure and anti-slip properties to a wide variety of paints and coatings

- Provides a consistent medium textured coating surface

- Tough, high molecular weight polypropylene gives good film durability

- Does not lower COF; ideal for anti-skid surfaces

- Easy to disperse powder that can be incorporated with high speed mixing

- Adds texture in low bake (Low E) powder coatings

PropylTex® 140S

Request SampleCoarse particle size grades of micronized polypropylene for adding texture, structure and anti-slip properties to a wide variety of paints and coatings

- Provides a consistent medium textured coating surface

- Tough, high molecular weight polypropylene gives good film durability

- Does not lower COF; ideal for anti-skid surfaces

- Easy to disperse powder that can be incorporated with high speed mixing

- Adds texture in low bake (Low E) powder coatings

PropylTex® 200HD

Request SampleMedium particle size grade of densified micronized polypropylene for adding consistent surface texture and structure with excellent in-can stability in water based paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Particle density optimized to essentially eliminate flotation or settling in water based systems

- Adds a mild to medium texture to the coating surface

- Tough, high molecular weight polypropylene gives good durability

- Does not lower COF; ideal for anti-skid surfaces

PropylTex® 200S

Request SampleCoarse particle size grades of micronized polypropylene for adding texture, structure and anti-slip properties to a wide variety of paints and coatings

- Provides a consistent medium textured coating surface

- Tough, high molecular weight polypropylene gives good film durability

- Does not lower COF; ideal for anti-skid surfaces

- Easy to disperse powder that can be incorporated with high speed mixing

- Adds texture in low bake (Low E) powder coatings

PropylTex® 200SF

Request SampleCoarse particle size grades of micronized polypropylene for adding texture, structure and anti-slip properties to a wide variety of paints and coatings

- Provides a consistent medium textured coating surface

- Tough, high molecular weight polypropylene gives good film durability

- Does not lower COF; ideal for anti-skid surfaces

- Easy to disperse powder that can be incorporated with high speed mixing

- Adds texture in low bake (Low E) powder coatings

PropylTex® 230HD

Request SampleMedium particle size grade of densified micronized polypropylene for adding consistent surface texture and structure with excellent in-can stability in water based paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Particle density optimized to essentially eliminate flotation or settling in water based systems

- Adds a mild to medium texture to the coating surface

- Tough, high molecular weight polypropylene gives good durability

- Does not lower COF; ideal for anti-skid surfaces

PropylTex® 230S

Request SampleMedium particle size grade of micronized polypropylene for adding consistent texture and structure to a wide variety of paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Adds a medium texture effect to the coating surface

- Tough, high molecular weight polypropylene gives good durability

- Does not lower COF; ideal for anti-skid surfaces

- Narrow cut mean particle size grades available for maximum texture control

- Adds texture in low bake (Low E) powder coatings

PropylTex® 270HD

Request SampleFine particle size grade of densified micronized polypropylene for adding consistent surface texture and structure with excellent in-can stability in water based paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Particle density optimized to essentially eliminate flotation or settling in water based systems

- Adds a mild texture to the coating surface

- Tough, high molecular weight polypropylene gives good durability

- Does not lower COF; ideal for anti-skid surfaces

PropylTex® 270S

Request SampleMicronized polypropylene for reducing gloss and adding consistent surface texture and structure to a wide variety of paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Adds a mild texture effect to the coating surface

- Tough, high molecular weight polypropylene gives good durability

- Does not lower COF; ideal for anti-skid surfaces

- Narrow cut mean particle size grades available for maximum texture control

- Adds texture in low bake (Low E) powder coatings

PropylTex® 325HD

Request SampleFine particle size grade of densified micronized polypropylene for adding consistent surface texture and structure with excellent in-can stability in water based paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Particle density optimized to essentially eliminate flotation or settling in water based systems

- Adds a mild texture to the coating surface

- Tough, high molecular weight polypropylene gives good durability

- Does not lower COF; ideal for anti-skid surfaces

PropylTex® 325S

Request SampleMicronized polypropylene for reducing gloss and adding consistent surface texture and structure to a wide variety of paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Adds a mild texture effect to the coating surface

- Tough, high molecular weight polypropylene gives good durability

- Does not lower COF; ideal for anti-skid surfaces

- Narrow cut mean particle size grade available for maximum texture control

- For a finer texture, try PropylMatte 31

PropylTex® 50

Request SampleExtra coarse particle size grades of micronized polypropylene for adding texture, structure and anti-slip properties to a wide variety of paints and coatings

- Provides a consistent coarse textured coating surface

- Tough, high molecular weight polypropylene gives good film durability

- Does not lower COF; ideal for anti-skid surfaces

- Easy to disperse powder that can be incorporated with high speed mixing

Superslip 6515

Request SampleEconomical combination of polyethylene and amide wax that provides scratch and mar resistance with a smooth surface feel

- Polyethylene provides scratch and mar resistance

- EBS provides maximum surface lubricity and block resistance without the use of PTFE

- Imparts a smooth surface "feel"

Superslip 6515AL

Request Sample

A highly engineered HDPE/EBS/aluminum oxide nanocomposite for maximum scratch, scuff and block resistance

- Maximum scratch resistance; equal to PE/PTFE additives

- HDPE/amide wax composite reinforced with 300 nm aluminum oxide nanoparticles (Mohs Hardness 9)

- Good abrasion resistance with slip and lubricity

- Amide wax component provides excellent antiblocking and release properties

- Ideal for can and container coatings; 21CFR 175.300 approved

AquaBead® R331E

Request Sample

A high solids nonionic rice bran wax emulsion providing water repellency and lubricity with excellent rub and abrasion resistance

- Based on natural, biodegradable, sustainable and upcycled rice bran wax

- Adds slip and rub resistance to high gloss inks and coatings

- Excellent abrasion resistance

- Outstanding water repellency/beading properties superior to paraffin emulsions

- Developed for broad compliance in food packaging and agrochemicals

GraphShield 777

Request SampleA versatile soluble nanocomposite powder of graphene and acrylic resin for liquid coatings

- Dry graphene composite powder is soluble in both solvent (alcohols, glycols, glycol ethers) and alkaline water based systems for easy incorporation into most coatings

- Graphene can improve corrosion resistance, mechanical durability, and electrostatic dissipation properties

- For best results, pre-dissolve in a glycol ether compatible with your solvent or waterbased coating

- More stable and versatile than graphene dispersions

- Formulated exclusively with Asbury Carbons EFG technology

- Easier-to-disperse nanotechnology in a safe, non-nano powder

MicroTouch 875XF

Request Sample

Naturally derived modified spherical polyurethane beads that can modify the tactile properties of formulated coatings and inks while improving burnish, scratch and mar resistance

- Virtually indestructible elastic particles that distort when disturbed by a physical force and then return to their original spherical shape when the force is removed

- Provide different tactile effects ranging from satiny smooth to rubbery to leathery in properly formulated coatings

- Naturally derived; Renewable Carbon Index (RCI) >61%

- Modified to enhance surface slip and lubricity

- Improves burnish and abrasion resistance

- Effective gloss reduction

NatureTex® 140

Request Sample

Micronized naturally derived cellulose acetate for reducing gloss and adding consistent surface texture and structure to a wide variety of paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Adds mild to moderate texture effects to the coating surface

- Naturally derived and biodegradable in both freshwater and marine environments

- High melting point

- Hydroxyl functionality (OH value 116)

- Microplastic alternative

NatureTex® 270

Request Sample

Micronized naturally derived cellulose acetate for reducing gloss and adding consistent surface texture and structure to a wide variety of paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Adds mild to moderate texture effects to the coating surface

- Naturally derived and biodegradable in both freshwater and marine environments

- High melting point

- Hydroxyl functionality (OH value 116)

- Microplastic alternative

NatureTex® 200

Request Sample

Micronized naturally derived cellulose acetate for reducing gloss and adding consistent surface texture and structure to a wide variety of paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Adds mild to moderate texture effects to the coating surface

- Naturally derived and biodegradable in both freshwater and marine environments

- High melting point

- Hydroxyl functionality (OH value 116)

- Microplastic alternative

NatureTex® 325

Request Sample

Micronized naturally derived cellulose acetate for reducing gloss and adding consistent surface texture and structure to a wide variety of paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Adds mild to moderate texture effects to the coating surface

- Naturally derived and biodegradable in both freshwater and marine environments

- High melting point

- Hydroxyl functionality (OH value 116)

- Microplastic alternative

Microspersion® EZ-2

Request SampleA synergistic blend of surfactants ideal for making waterbased wax dispersions

- Improved stability vs. Microspersion EZ

- Use 4% Microspersion EZ-2 with (optionally) a defoamer to disperse up to 50% wax solids

- HLB of 8.7

- 40CFR Part 180 compliant for seed and agricultural systems

- For maximum wax dispersion storage stability, postadd a thickening agent to increase viscosity and slow wax flotation

- Refer to our brochure and video on "How to Disperse Micronized Wax" for complete use instructions

MP-28AL

Request SampleValue engineered synthetic wax/aluminum oxide nanocomposites for surface durability and lubricity

- Improves scratch, scuff and mar resistance

- Adds surface slip and lubricity

- Choose XF grade for maximum gloss retention

- Choose G grade for maximum gloss reduction and burnish resistance

- Biodegradable to OECD 302C test standard

- Not a microplastic per ECHA definitions

NatureMatte® C44

Request Sample

Fine cellulose powder for superior gloss reduction with excellent viscosity stability

- Highly effective matting additive capable of achieving single digit gloss (60°)

- Superior in-can stability with no impact on rheology

- Biodegradable

- Natural, sustainable, and renewable

- Microplastic alternative

PolyTuf® 1229

Request SampleA highly engineered LDPE/ceramic/nanoceramic composite for abrasion resistance and surface durability

- High performance additive for maximizing surface abrasion resistance (Taber) and film toughness

- Fortified with two types of hard, inert ceramic particles

- Low density polyethylene provides superior surface toughness, durability and mar resistance

- Ideal for walking surfaces

- PTFE-free alternative to Polyfluo 900

- Easy to disperse fine powder that can be incorporated with high speed mixing

AquaPoly 250G

Request SampleA unique micronized polyethylene wax blend for maximum rub and scratch resistance with improved slip in aqueous systems

- A hard, high density modified polyethylene blend

- Provides outstanding rub, mar and scratch resistance

- Adds slip properties

- Imparts antiblocking

PropylTex® 270-18523HD

Request SampleFine particle size grade of densified micronized polypropylene for adding consistent surface texture and structure with excellent in-can stability in water based paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Particle density optimized to essentially eliminate flotation or settling in water based systems

- Adds a mild texture to the coating surface

- Tough, high molecular weight polypropylene gives good durability

- Does not lower COF; ideal for anti-skid surfaces

PropylTex® 270S-16520

Request SampleMicronized polypropylene for reducing gloss and adding consistent surface texture and structure to a wide variety of paints and coatings

- Provides gloss reduction with improved burnish resistance vs. silica

- Adds a mild texture effect to the coating surface

- Tough, high molecular weight polypropylene gives good durability

- Does not lower COF; ideal for anti-skid surfaces

- Narrow cut mean particle size grades available for maximum texture control

- Adds texture in low bake (Low E) powder coatings

NyloTex 100

Request SampleMicronized Nylon 66 for adding texture and surface durability to high temperature coatings

- Provides a uniform and controlled surface texture

- Imparts surface toughness and durability

- High melting point polymer is ideal for use in baking or high temperature curing systems

- Easy to disperse fine powder that can be incorporated with high speed mixing

- Adds texture in powder coatings

Microspersion® 1229-40

Request SampleA water based dispersion of a highly engineered LDPE/ceramic/nanoceramic composite for abrasion resistance and surface durability

- Convenient, ready-to-use, pourable water based wax dispersion

- High performance additive for maximizing surface abrasion resistance (Taber) and film toughness

- Fortified with two types of hard, inert ceramic particles

- Low density polyethylene provides superior surface toughness, durability and mar resistance

- Ideal for walking surfaces

- Effective replacement for PTFE additives

Microspersion® 6515AL-30

Request SampleA water based dispersion of a highly engineered HDPE/amide wax/aluminum oxide nanocomposite for maximum scratch, scuff and block resistance

- Convenient, ready-to-use, pourable water based wax dispersion

- Maximum scratch resistance; equal to PE/PTFE additives

- HDPE/amide wax composite reinforced with 300 nm aluminum oxide nanoparticles (Mohs Hardness 9)

- Good abrasion resistance with slip and lubricity

- Amide wax component provides excellent antiblocking and release properties

- Ideal for can and container coatings; 21CFR 175.300 approved

Microspersion® 28AL-50

Request SampleA water based dispersion of a value engineered synthetic wax/aluminum oxide nanocomposite for scratch and scuff resistance

- Convenient, ready-to-use, pourable water based wax dispersion

- Improves scratch, scuff and mar resistance

- Adds surface slip and lubricity

- Excellent gloss retention

- Biodegradable to OECD 302C test standard

- Not a microplastic per ECHA definitions

Microspersion® 510E

Request SampleA nonionic polyethylene wax emulsion for improving surface properties in water based coatings

- Imparts slip, scuff and abrasion resistance

- Improves mar resistance, block resistance and slide angle of water based inks, coatings and overprint varnishes

- Adds early water resistance

- Provides optimum surface protection while maintaining excellent gloss and film clarity

Superslip 6515AL-EZ

Request Sample

An easy to disperse HDPE/EBS/aluminum oxide nanocomposite for maximum scratch, scuff and block resistance

- Maximum scratch resistance; equal to PE/PTFE additives

- Surface treated powder for effortless dispersion into waterbased systems

- HDPE/EBS composite reinforced with 300 nm aluminum oxide nanoparticles (Mohs Hardness 9)

- Good abrasion resistance with slip and lubricity

- Amide wax component provides excellent antiblocking and release properties

- Ideal for can and container coatings; 21CFR 175.300 approved

MicroMatte® 1415-EZ

Request SampleA multifunctional matting additive that improves soil release and dirt pickup resistance in architectural coatings

- Complex wax composite dramatically improves DPUR vs. inorganic flattening agents

- Provides efficient gloss reduction

- Improves burnish resistance

- Surface treated for easy incorporation into waterbased systems

- Particle density provides optimal in-can stability

- Not classified as a microplastic

MP-28AL-XF

Request SampleValue engineered synthetic wax/aluminum oxide nanocomposites for surface durability and lubricity

- Improves scratch, scuff and mar resistance

- Adds surface slip and lubricity

- Choose XF grade for maximum gloss retention

- Choose G grade for maximum gloss reduction and burnish resistance

- Biodegradable to OECD 302C test standard

- Not a microplastic per ECHA definitions

MP-28AL-G

Request SampleValue engineered synthetic wax/aluminum oxide nanocomposites for surface durability and lubricity

- Improves scratch, scuff and mar resistance

- Adds surface slip and lubricity

- Choose XF grade for maximum gloss retention

- Choose G grade for maximum gloss reduction and burnish resistance

- Biodegradable to OECD 302C test standard

- Not a microplastic per ECHA definitions

Download Selector Guide

Download Selector Guide